Abstract

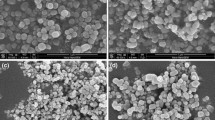

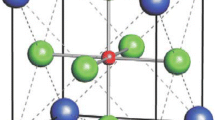

Highly stable, water-based barium titanate (BaTiO3) sols were developed by a low cost and straightforward sol–gel process. Nanocrystalline barium titanate thin films and powders with various Ba:Ti atomic ratios were produced from the aqueous sols. The prepared sols had a narrow particle size distribution in the range 21–23 nm and they were stable over 5 months. X-ray diffraction pattern revealed that powders contained mixture of hexagonal- or perovskite-BaTiO3 as well as a trace of Ba2Ti13O22 and Ba4Ti2O27 phases, depending on annealing temperature and Ba:Ti atomic ratio. Highly pure barium titanate with cubic perovskite structure achieved with Ba:Ti = 50:50 atomic ratio at the high temperature of 800 °C, whereas pure barium titanate with hexagonal structure obtained for the same atomic ratio at the low temperature of 500 °C. Transmission electron microscope revealed that the crystallite size of both hexagonal- and perovskite-BaTiO3 phases reduced with increasing the Ba:Ti atomic ratio, being in the range 2–3 nm. Scanning electron microscope analysis revealed that the average grain size of barium titanate thin films decreased with an increase in the Ba:Ti atomic ratio, being in the range 28–35 nm. Moreover, based on atomic force microscope images, BaTiO3 thin films had a columnar-like morphology with high roughness. One of the highest specific surface area reported in the literature was obtained for annealed powders at 550 °C in the range 257–353 m2g−1.

Similar content being viewed by others

References

Kim YI, Jung JK, Ryu KS (2004) Mater Res Bull 39:1045

Hu MZC, Payzant VKEA, Rawn CJ, Hunt RD (2000) Powder Technol 110:2

Kwei GH, Lawson AC, Billinge SJL (1993) J Phys Chem 97:2368

Kwon SW, Yoon DH (2007) J Eur Ceram Soc 27:247

Kwon SW, Yoon DH (2007) Ceram Int 33:1357

Yen FS, Hasing HL, Chang YH (1995) Jpn J Appl Phys 34:6149

Ihlefeld JF, Borland WJ, Maria JP (2008) J Mater Sci 43:4264. doi:10.1007/s10853-008-2618-x

Yaseen H, Baltianski S, Tsur Y (2007) J Mater Sci 42:9679. doi:10.1007/s10853-007-1944-8

Hung KM, Hsieh CS, Yang WD, Sun YJ (2007) J Mater Sci 42:2376. doi:10.1007/s10853-006-1452-2

Wang L, Liu L, Xue D, Kang H, Liu C (2007) J Alloys Compd 440:78

Ischenko V, Pippel E, Ko¨ferstein R, Abicht HP, Woltersdorf J (2007) Solid State Sci 9:21

Baeten F, Derks B, Coppens W, van Kleef E (2006) J Eur Ceram Soc 26:589

Jhung SH, Lee JH, Yoon JW, Hwang YK, Hwang JS, Park SE, Chang JS (2004) Mater Lett 58:3161

Zhang S, Jiang F, Qu G, Lin C (2008) Mater Lett 62:2225

Harizanov O, Harizanova A, Ivanova I (2004) Mater Sci Eng B106:191

Novak Z, Knez Z, Ban I, Drofenik M (2001) J Supercrit Fluids 19:209

Matsuda H, Kobayashi N, Kobayashi T, Miyazawa K, Kuwabara M (2000) J Non-Cryst Solids 271:162

Kumazawa H, Masuda K (1999) Thin Solid Films 353:144

Cheung MC, Chan HLW, Zhou QF, Choy CL (1991) Nanostruct Mater 11:837

Tangwiwat S, Milne SJ (2005) J Non-Cryst Solids 351:976

Fujihara S, Schneller T, Waser R (2004) Appl Surf Sci 221:178

Lee B, Zhang J (2001) Thin Solid Films 388:107

Lide DR (2007) Handbook of chemistry and physics, 87th edn. CRC Press, Ohio, p 4

Guo W, Datye AK, Ward TL (2005) J Mater Chem 15:470

Mohammadi MR, Cordero-Cabrera MC, Ghorbani M, Fray DJ (2006) J Sol–Gel Sci Technol 40:15

Mohammadi MR, Cordero-Cabrera MC, Fray DJ, Ghorbani M (2006) Sens Actuators B: Chem 120:86

Kishi A, Toraya H (2004) Rigaku J 21:25

Cullity BD (1978) Elements of X-ray diffraction. Addison-Wesley Publishing Company, Inc., London, p 99

Liu X, Yang J, Wang L, Yang X, Lu L, Wang X (2000) Mater Sci Eng A 289:241

Ivanova T, Harizanova A, Surtchev M (2002) Mater Lett 55:327

Socrates G (1994) Infrared characteristic group frequencies: tables and charts. Wiley, England, p 6 (62 and 237)

Cho WS (1998) J Phys Chem Solids 59:659

Takaoka GH, Hamamo T, Fukushima K, Matsuo J, Yamada I (1997) Nucl Instr Meth Phys Res B 121:503

Mohammadi MR, Fray DJ (2007) Acta Mater 55:4455

Dicken MJ, Diest K, Park YB, Atwater HA (2007) J Cryst Growth 300:330

Canulescu S, Dinescu G, Epurescu G, Matei DG, Grigoriu C, Craciun F, Verardi P, Dinescu M (2004) Mater Sci Eng B 109:160

Webb PA, Orr C (1997) Analytical methods in fine particle technology. Micromeritics Instrument Corporation, USA, p 55

Acknowledgement

The authors wish to acknowledge Mr. David Nicol for his help with TEM analysis.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mohammadi, M.R., Rad, A.E. & Fray, D.J. Water-based sol–gel nanocrystalline barium titanate: controlling the crystal structure and phase transformation by Ba:Ti atomic ratio. J Mater Sci 44, 4959–4968 (2009). https://doi.org/10.1007/s10853-009-3758-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-009-3758-3